Selecting the right airplane engine oil is a critical decision in maintaining an aircraft engine’s optimal performance and longevity. The diversity of airplane engine oils available on the market can be overwhelming, and making an informed choice involves considerations beyond the basic oil change intervals. This exploration delves into the nuanced factors that guide the selection of airplane engine oils, ranging from the specific needs of the engine to the environmental conditions in which the aircraft operates.

Understanding Viscosity: Matching Engine Requirements with Oil Characteristics

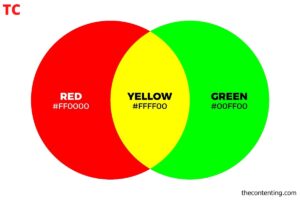

Viscosity, a measure of an oil’s resistance to flow, is a fundamental consideration in choosing the right engine oil. Different aircraft engines have varying requirements for viscosity, and selecting oil with the appropriate viscosity ensures proper lubrication and engine protection. The Society of Automotive Engineers (SAE) viscosity grading system classifies oils, with lower numbers representing thinner oils and higher numbers indicating thicker ones.

Understanding the engine manufacturer’s recommendations and considering factors such as temperature extremes and startup conditions are crucial. The science behind viscosity selection lies in balancing maintaining oil flow at low temperatures and providing sufficient lubrication under high-temperature operating conditions.

Synthetic vs. Conventional Oils: Weighing Performance and Cost Factors

The choice between synthetic and conventional aircraft engine oils introduces a nuanced decision-making process. Synthetic oils, formulated with advanced chemical engineering, offer enhanced performance characteristics, including better viscosity stability, oxidation resistance, and protection against engine deposits. While synthetic oils often come at a higher cost, their extended service intervals and superior performance in extreme conditions can justify the investment.

Conventional oils, derived from crude oil, remain a cost-effective option but can require more frequent changes. The science behind this choice involves assessing the aircraft’s operational profile, considering factors such as climate, flight frequency, and engine design. To determine whether the superior performance of synthetic oils aligns with the engine’s requirements and justifies the additional cost.

Aircraft Engine Specifications: Adhering to Manufacturer Recommendations

Manufacturers provide specific recommendations for engine oils based on the design and specifications of their aircraft engines. Deviating from these recommendations can compromise performance, potentially leading to increased wear, reduced efficiency, and even engine damage. Knowing the manufacturer’s guidelines regarding oil type, viscosity, and any specific additives ensures that the selected oil aligns with the engine’s engineering and design parameters. The logic behind this aspect lies in the meticulous engineering of aircraft engines, where tolerances, materials, and operating conditions are precisely calibrated. Adhering to manufacturer recommendations is a cornerstone of responsible maintenance, safeguarding the engine’s performance and integrity throughout its operational life.

Additives and Special Formulations: Tailoring Oil Composition to Needs

Airplane engine oil formulations often include additives to enhance specific performance characteristics. Additives can improve anti-wear properties, inhibit corrosion, and enhance thermal stability. The selection of oil with the right additives depends on the engine’s requirements and the operational context.

For instance, aircraft operating in extreme temperatures or under heavy loads can benefit from oils with specialized formulations. Behind these additives involves a deep understanding of the chemical interactions between oil components and engine surfaces. Tailoring the oil composition through additives addresses specific challenges posed by engine operation and contributes to overall performance and longevity.

Environmental Considerations: Balancing Performance with Eco-Friendliness

Environmental considerations are increasingly shaping decisions in the aviation industry, and the choice of engine oil is no exception. Opting for oils with lower environmental impact, such as those with extended service intervals, supports sustainability initiatives. Balancing performance requirements with eco-friendly options involves evaluating the environmental footprint of different oils, considering factors like biodegradability and recyclability.

This decision lies in recognizing the interconnectedness of aviation operations with broader environmental concerns. By prioritizing oils that minimize waste and reduce the frequency of oil changes. Its operators contribute to sustainable aviation practices without compromising the engine’s performance.

Conclusion

Choosing the right type of airplane engine oil for an aircraft is a precision decision. It requires careful consideration of various factors. Navigating the complexity involves understanding viscosity requirements, and weighing the benefits of synthetic versus conventional oils. It must adhere to manufacturer specifications, consider additives and special formulations, and address environmental considerations. These decisions intertwine principles of chemistry, materials engineering, and environmental science. As aviation progresses, selecting the most suitable engine, oil becomes not just a maintenance task but a strategic choice that influences the performance, efficiency, and sustainability of aircraft operations. Making informed decisions in engine oil selection is, therefore, a key aspect of responsible aircraft maintenance practices.